section-24ca95c

SIRI – SMART INDUSTRY READINESS INDEX

The Smart Industry Readiness Index (SIRI) is the world’s first independent digital maturity assessment system recognized by the World Economic Forum (WEF) that assesses the digital maturity level of manufacturing facilities and supports their transition to Industry 4.0.

Companies aiming to adopt Industry 4.0 often have different starting points. Regardless of where they start, their size or the field they work in, all companies can benefit from Industry 4.0.

SIRI provides an unbiased and comprehensive framework for assessing companies’ readiness for Industry 4.0. This framework helps companies understand their current situation and identify areas for improvement.

It also provides practical and usable tools to help manufacturers determine where to start with digital transformation, how to scale it and what they can do to sustain growth.

It allows manufacturing companies to compare their current maturity levels with international companies and within their own sectors with an unbiased assessment. This assessment helps companies determine the necessary steps to achieve their future goals and identify priority areas for improvement, regardless of their size, sector and digital maturity.

The SIRI Framework and Assessment Matrix tool provides manufacturing companies with practical information on.

- What I4.0 is and the tangible benefits it can provide.

- The maturity levels of their organizations and facilities.

- How they can make targeted and incremental improvements.

“Although the term Industry 4.0 was coined some time ago, many manufacturing companies, especially SMEs, are still unfamiliar with the concept. The SIRI Framework is an intuitive and realistic reference framework that will help all industrial companies, large and small, not only learn these new concepts, but also apply them to our facilities.”

- Mr. Desmond Goh, Direktör, People Bee Hoon Factory

section-ae98571

THE SIRI FRAMEWORK

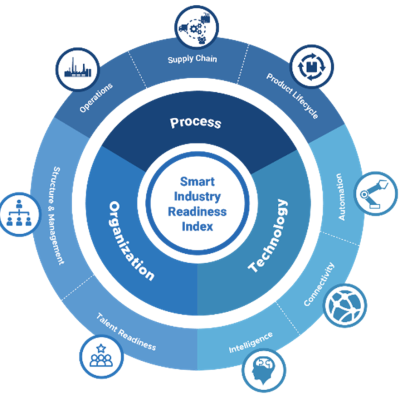

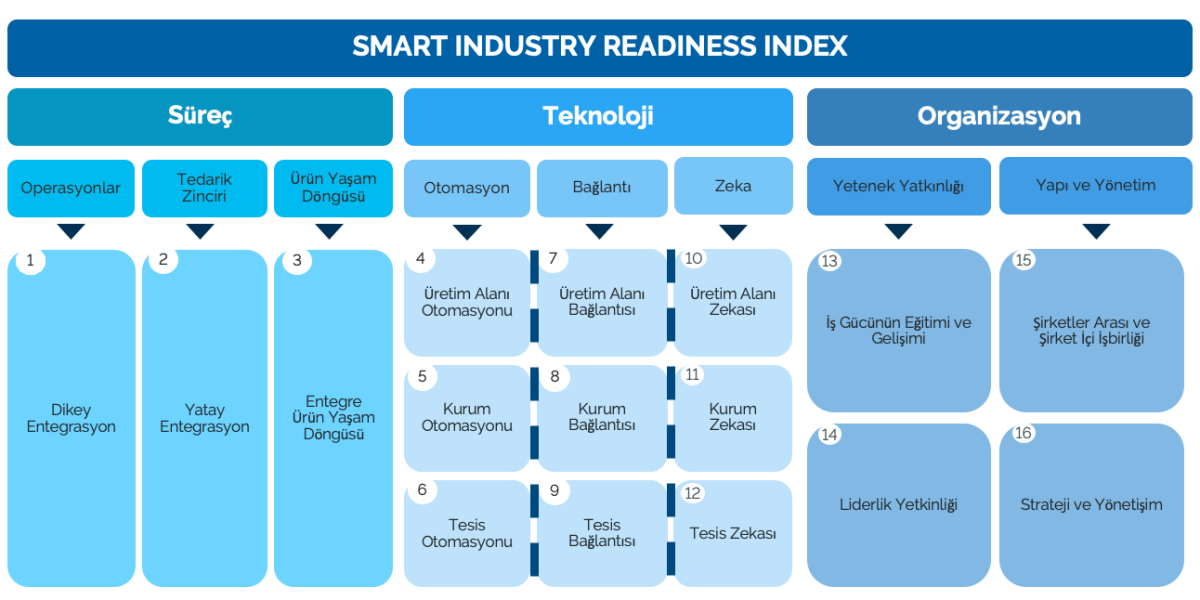

The SIRI Framework is three-layered. The top layer identifies the 3 key building blocks that need to be considered to transform any factory or facility into a factory/facility of the future – Technology, Process and Organization. All 3 building blocks must be considered to realize the full potential of Industry 4.0.

The 8 key pillars supporting the 3 building blocks represent the critical areas that companies need to focus on to become future-ready organizations under the Industry 4.0 reference model.

The third and final layer consists of 16 dimensions that companies should refer to when assessing the current maturity level of their facilities.

LEAD

L (LEARN)

E (EVALUATE)

A (ARCHITECT)

D (DELIVER)

It is a continuous and iterative four-step process that manufacturing companies can adopt in their approach to Industry 4.0 transformation.

These steps, covered in the LEAD framework, will help companies determine where to start, how to scale, and how to sustain growth in a world powered by Industry 4.0.

EVALUATION PROCESS

The SIRI Digital Maturity Assessment study is completed with 3 meetings planned over a period of approximately 4 - 6 weeks, and the Official SIRI Report is delivered to the company participating in the study.

The ideal number of participants within the scope of the Assessment Matrix study can vary between 5-15 depending on the size of the company. The current status of the institution is analyzed in 16 dimensions with the field analysis and the evaluation meeting held with the relevant unit managers. A band score between 0 and 5 is determined for each dimension in response to the digital maturity level.

The prioritization study is used to determine the business areas where improvements will add the most value in parallel with the company's strategy and future goals. Therefore, it is a critical step in determining a feasible roadmap. It should be noted that all dimensions should be taken into account, but the relative importance of each will vary depending on the company's needs and the sector in which it operates.