section-24ca95c

END ENERGY

section-bd18706

Featured Features

- Instant measurement of resource usage

- Location/facility based

- Machine based

- Time based

- Energy cost on job order, piece-by-piece and/or machine basis

- Energy consumed from raw material to finished product

- ISO 50001 Energy Management System compatible structure

- Energy consumption simulation

- Instant traceability of temperature and humidity data of chemical warehouses

- Traceability of in-plant temperature and humidity information

- Warning systems for energy increases that damage machines

- Machine-based comparison screens

- ERP integration

- Independent of analyzer/device brand and model

- Easy to use and web-based architecture

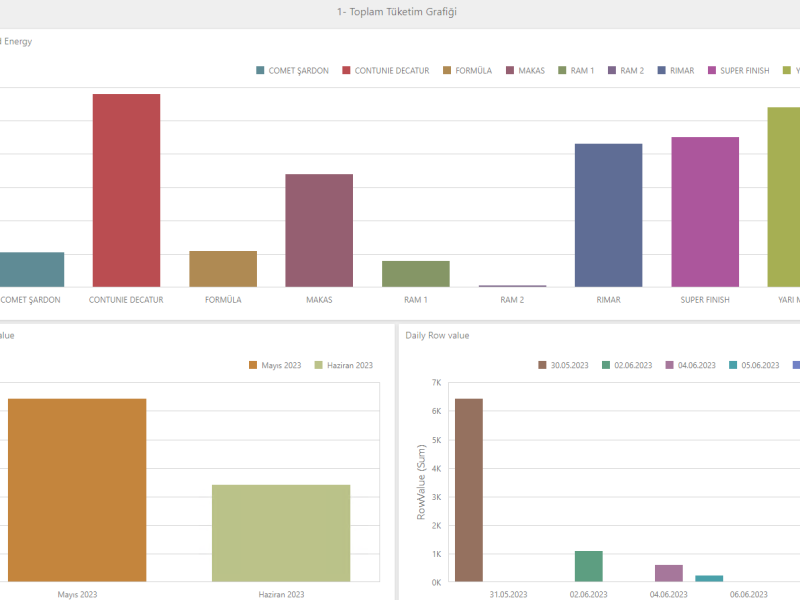

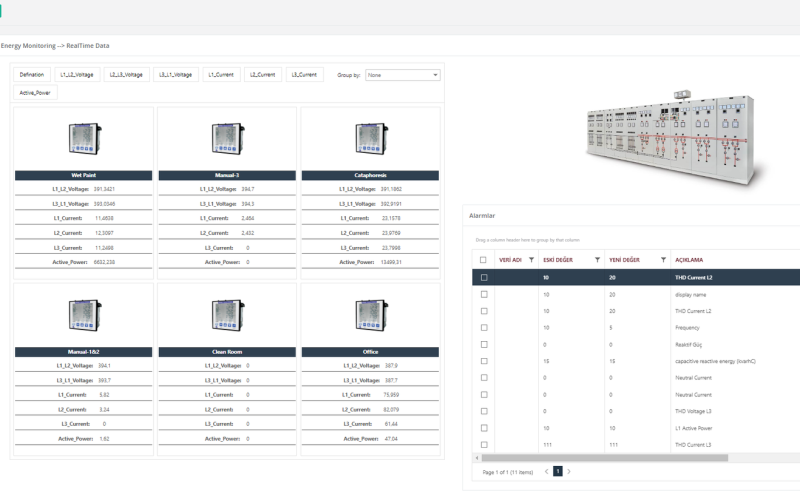

- Real-time monitoring and reporting

- Adaptable business intelligence dashboard

- Language options (Turkish and English)

section-d048863

Enerji tüketiminin yoğun olarak gerçekleştiği endüstriyel tesislerde enerjinin nerede ve nasıl kullanıldığını anlamak ve izlemek çok önemlidir. END Energy, enerji analizörlerinin ölçtüğü değerler ile enerji kullanımı ve kalitesini gerçek zamanlı izlemenizi ve yönetmenizi sağlar. Güç kalitesinin önemi ve enerji maliyetleri gün geçtikçe artarken, harcanan enerjinin verimliliğini ölçmek ve üretilen parça başına maliyeti hesaplamak, görünürlüğü arttırdığı için işletmelerin genel ve üretim giderlerini azaltmakta ve bakım ihtiyaçlarını düşürmektedir. Güç kalitesinin önemi ve enerji maliyetleri gün geçtikçe artarken, harcanan enerjinin verimliliğini ölçmek ve üretilen parça başına maliyeti hesaplamak,görünürlüğü arttırdığı için işletmelerin genel ve üretim giderlerini azaltmakta ve bakım ihtiyaçlarını düşürmektedir.

END Energy ensures that companies that want to establish a structure compatible with the ISO 50001 Energy Management System create the necessary infrastructure and implement processes that will allow the base energy consumption of the facility to be understood. It will ensure that action plans are created, targets are set to reduce consumption and energy performance indicators are created, and improvement opportunities are identified, prioritized and recorded to improve energy performance.

The values measured by END Energy can be monitored in real time via the web-based interface of the solution via mobile devices, tablets, etc.

Thanks to energy consumption simulation, companies can calculate estimated energy consumption amounts for future production scenarios. In order to reduce electrical waste, the energy plan can be determined according to the data obtained by calculating the costs and relationships of the loads (machine use, heating, cooling).

section-ae98571

END ENERGY and END MES Integration

Thanks to the integration with END MES, which works in a controlled manner without the need for human intervention in many different stages of production operations, companies collect data from energy analyzers and production at a single point, continuously record and monitor the changes that occur.

Actual average cycle time, standard-actual production analysis, production rate, amount produced per unit time and energy consumed, line efficiency, production completion time, machine failure frequency, etc. analyzes and firm's overall overall labor effectiviness (OLE), overall equipment effectiveness (OEE) and total effective equipment performance (TEEP), etc. Performance analysis can be done with END MES.

After this integration, which is the first stage of optimizing production times and energy consumption, it is possible to create the structure that will be used to estimate production times and energy consumption amounts using data mining and machine learning algorithms.